Hose/wire Reel Drive Types and Characteristics

December 18, 2025 | Industrial Hose Reels

I. Primary Drive Type Classification

1. Manual Drive

- Working Principle: Relies entirely on human force to pull out the hose/cable, followed by manual cranking or spring-assisted rewind.

- Common Variants:

- Simple Crank Type: Uses a handle and gearbox to increase rewinding force.

- Spring-Rewind (Retractable) Type: A spring stores energy during payout; releasing a lock triggers automatic rewind (e.g., common garden hose reels, vacuum cleaner cord reels).

- Characteristics:

- Advantages: Simple structure, low cost, portable, requires no external power, easy maintenance.

- Disadvantages: Labor-intensive, slow rewind speed, unsuitable for heavy/long lines, low level of automation.

- Typical Applications: Garden hoses, small power tool cables, charging cables, light-duty air hoses on job sites, cleaning equipment.

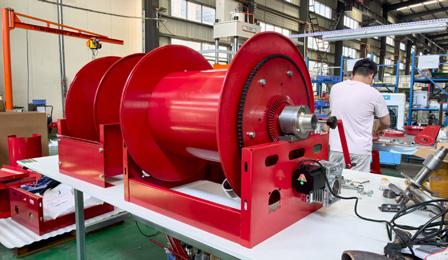

2. Electric Drive

- Working Principle: Uses an electric motor for power. Pay-out and rewind are controlled via a button or switch.

- Common Variants:

- AC Electric: Plugs into industrial power grids (220V/380V), high power.

- DC Electric: Typically uses batteries (e.g., 12V/24V) or vehicle power sockets, offering high mobility.

- Characteristics:

- Advantages: Effortless and efficient, push-button operation, fast and neat rewinding; can integrate overload protection, remote control, etc.; capable of handling heavy-duty, long-length lines.

- Disadvantages: Higher cost; requires a power source, limiting use in some remote locations; relatively complex structure requiring some maintenance.

- Typical Applications: Factory equipment cables, large welding machine cables, fire hoses, heavy-duty mining cables, stage lighting/audio cables.

3. Pneumatic (Air) Drive

- Working Principle: Uses compressed air to drive a pneumatic motor, which powers the reel.

- Characteristics:

- Advantages: Intrinsically safe and explosion-proof, ideal for hazardous environments with flammable gases or dust (e.g., oil & gas, chemical plants, mines, paint shops); powerful, relatively simple maintenance.

- Disadvantages: Requires a stable compressed air supply; limited by air line placement; often noisy; less energy-efficient than electric drives.

- Typical Applications: Oil rigs, chemical plants, coal mines, sandblasting workshops – any location with strict explosion-proof requirements.

4. Hydraulic Drive

- Working Principle: Powered by a hydraulic system driving a hydraulic motor.

- Characteristics:

- Advantages: Extremely high torque, can smoothly drive very heavy loads; excellent speed control and precision; compact design, high power density.

- Disadvantages: Most complex system, highest cost; risk of hydraulic fluid leaks; requires specialized maintenance; needs a hydraulic power source.

- Typical Applications: Ultra-heavy-duty cables for construction machinery, ship-to-shore power cables, large hydraulic equipment hoses, tool line reels on specialty vehicles (e.g., snow plows, street sweepers).

5. Idler/Passive (Pulled) Drive

- Working Principle: The reel itself has no motor. Its rotation is driven by the pulling force on the line (e.g., the line is anchored, a vehicle moves away to pay it out; rewinding occurs when the vehicle returns, pulling the line back onto the reel).

- Characteristics:

- Advantages: Extremely simple structure, no power required, low cost, reliable.

- Disadvantages: Rewinding is entirely dependent on external reverse force; cannot rewind actively; line may not spool neatly.

- Typical Applications: Towable irrigation systems, certain vehicle test lines, simple material guiding.

II. Key Selection Factors for Drive Type

Choosing the right drive type requires evaluating these factors:

- Power Source Availability: Is stable electrical power, compressed air, or hydraulic power available on-site? This is the primary constraint.

- Operating Environment & Safety:

- Standard workshop/warehouse → Electric drive.

- Hazardous (explosive) atmosphere → Must use Pneumatic drive or specially certified explosion-proof Electric drive.

- Outdoor, mobile vehicle → DC Electric or Hydraulic drive.

- Line Parameters & Load:

- Lightweight, short distance → Manual drive.

- Medium load, frequent use → Electric drive.

- Heavy-duty, large diameter, long distance → High-power Electric or Hydraulic drive.

- Frequency of Use & Automation Needs: Frequent use, requires fast/neat spooling → Electric, Pneumatic, or Hydraulic drive.

- Budget & Maintenance Costs: Manual is most economical; Hydraulic has the highest total cost of ownership.

III. Additional Features (Working in Conjunction with the Drive)

Beyond the core drive, modern reels often integrate these features:

- Slip Rings: Allow continuous transmission of power/medium (water, air, oil) while the reel is rotating, enabling “live” spooling during operation.

- Automatic Level-Wind System: Ensures neat, even line layering on the drum to prevent wear and tangling.

- Tension Control / Overload Protection: Prevents line breakage or motor damage.

- Brake / Locking Mechanism: Locks the line at any desired length.

- Ingress Protection (IP) Rating: e.g., IP54/IP65, indicates resistance to dust and water.

- Mounting Style: Wall-mounted, base-standing, ceiling-suspended, mobile cart, etc.

Summary Comparison Table

| Drive Type | Power Source | Key Advantages | Key Disadvantages | Typical Scenario |

|---|---|---|---|---|

| Manual | Human Force | Inexpensive, Portable, No Power Needed | Laborious, Inefficient, Limited Load | Household, Light Tools |

| Electric | Electricity | Efficient, Effortless, Easy Control, Feature-Rich | Requires Power Source, Not for Hazardous Areas* | Factories, Workshops, Stages |

| Pneumatic | Compressed Air | Explosion-Proof & Safe, Powerful | Requires Air Supply, Noisy | Oil & Gas, Chemical, Mining |

| Hydraulic | Hydraulic Fluid | Extremely High Torque, Smooth Control | Complex, Expensive, High Maintenance | Heavy Machinery, Ports, Special Vehicles |

| Idler/Passive | External Pull | Simple, Reliable, Low Cost | Cannot Rewind Actively | Towable Irrigation, Specific Conveyance |

*Unless specifically designed and certified for explosive atmospheres.