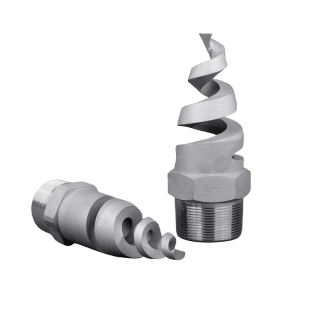

QJJ Plastic Quick Release Nozzle

QJJ Plastic Quick Release Nozzle is a versatile, tool-free quick-release spray nozzle designed for easy installation and fast maintenance. Its innovative quick-release structure allows the spray head to be removed from the nozzle body by hand with a simple 90° rotation, significantly reducing downtime. Built with chemical-resistant and wear-resistant materials such as glass fiber reinforced polypropylene, carbon fiber reinforced polypropylene, or PVDF, it offers high strength, corrosion resistance, and reliable sealing. Available in fan, solid cone, and hollow cone spray patterns with multiple connection sizes (1/8″, 1/4″, 3/8″), it’s ideal for cleaning, rinsing, cooling, humidification, chemical processing, PCB production, metal phosphating, and dust control applications.

Design features of QJJ plastic quick-release nozzle

Quick and convenient nozzle replacement technology The quick-release nozzle structure design is novel and scientific, and the nozzle body and nozzle can be separated quickly and effortlessly. You simply rotate the nozzle 90 degrees by hand. , you can remove it from the nozzle body and vice versa without any tools. Maintenance downtime can therefore be significantly reduced.

Automatic and accurate nozzle alignment The nozzle has a built-in stopper that locks the nozzle in the correct position after being installed into the nozzle body, eliminating time-consuming manual adjustments. As a result, every installation is guaranteed to be fully calibrated, eliminating quality control issues due to nozzle calibration errors.

The chemical-resistant and wear-resistant quick-release nozzle can be made of three materials: glass fiber reinforced polypropylene (containing 25% fiber), carbon fiber reinforced polypropylene (containing 40% fiber) and polyvinylidene fluoride (PVDF). All have the advantages of high strength, wear resistance and chemical corrosion resistance, and can prevent the flushing liquid from clumping and accumulation. Ideal for flushing, rinsing and cleaning applications with phosphates, acids, solvents and other corrosive solutions. Among them, glass fiber reinforced polypropylene has a heat resistance of 82°C, carbon fiber reinforced polypropylene has a heat resistance of 120°C, and polyvinylidene fluoride is a high-purity material without pigments, which can keep the processing environment highly purified. Under 7kg pressure Heat resistance up to 148℃.

Wide range of flow rate options. The nozzle body is available in three specifications: 1/8”, 1/4” and 3/8”. The inner layer of type 0 nitrile rubber sealing ring ensures absolute sealing between the nozzle body and the nozzle. Quick release nozzle The nozzle has a special shape for easy grip; the nozzle has three types: QC fan shape, QB solid cone shape and QA hollow cone shape, respectively providing three spray modes of fan shape, solid cone shape and hollow cone shape, and has a variety of flow rates and angles to choose from.

QJJ plastic quick release nozzle general application

-Production of printed circuit boards

-Product cleaning and rinsing

-Phosphating of metal parts

-Cooling

-Humidification

-Chemical manufacturing industry

-Dust control

| Material | Plastic, PVDF |

|---|---|

| Connection | 1/4″, 1/8", 3/8" |

| Min Pressure(bar) | 0.2 |

| Max Pressure(bar) | 14 |

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert